How It's Made

The process begins as a huge roll of aluminum is unrolled through a hot water bath and a straightener. Vinyl sheeting is applied with either the “First in Flight”, “First in Freedom” or the national/state motto design.

The aluminum is cut into 6” x 12” blanks. The tag’s corners are rounded and the four holes are punched. Blanks then go on racks to cure for 48 hours.

Alpha-numeric characters are set in place by hand under a press. Every license tag is pressed individually by manually changing the characters for each plate.

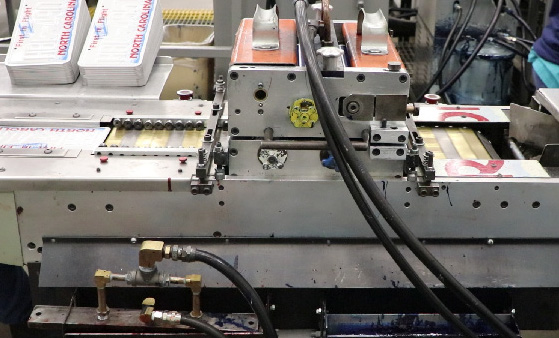

Tags are sent through a machine that applies paint to each of the raised characters.

After the paint is applied, tags run through a drier where they are manually collected.

Each tag is placed into an individual envelope and boxed, ready to ship.

Why Choose Correction Enterprises?

Because 12,832 Customers Believe We’re the Smart Choice and the Right Choice

At Correction Enterprises, our purpose-driven mission is like no other: To Create a Safer North Carolina through the Changing of Lives. How can you help? By partnering with us on the products and services you are already buying.

Why? Because it’s the Smart Choice and the Right Choice.